Fabric facility

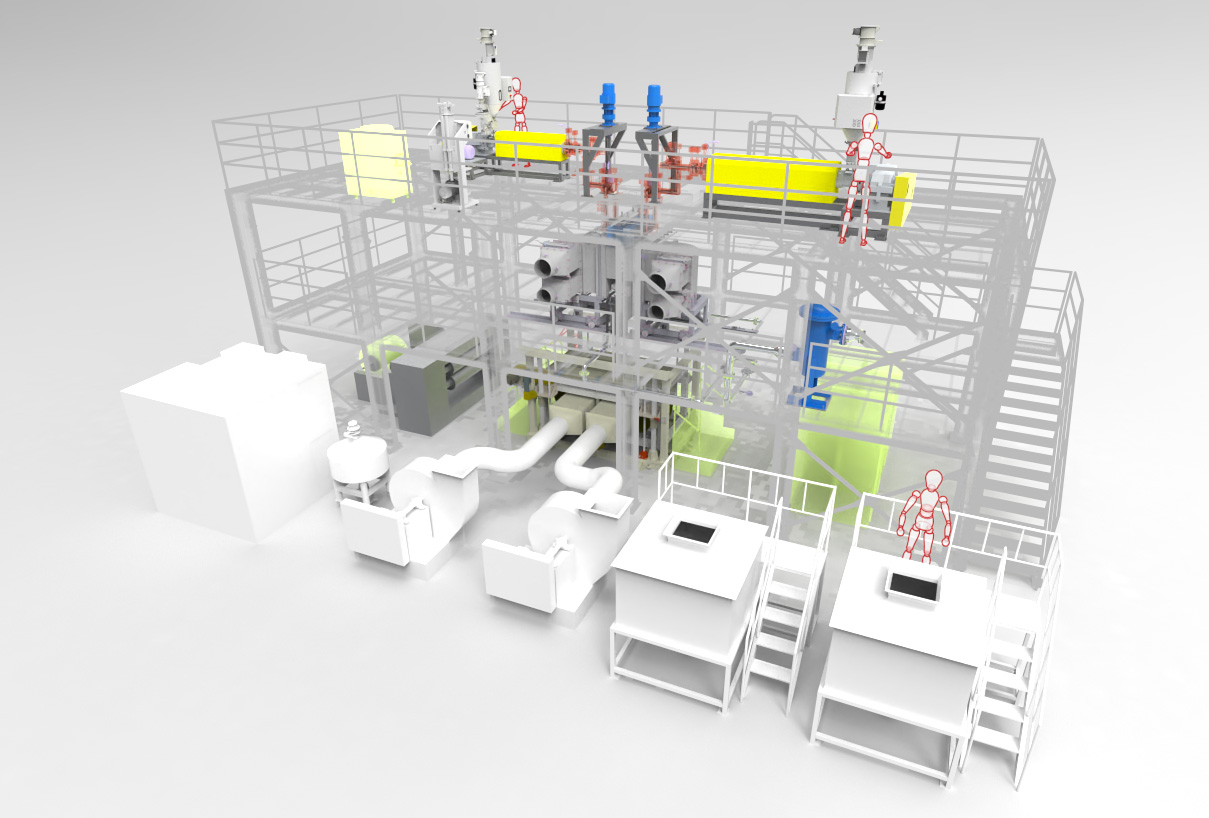

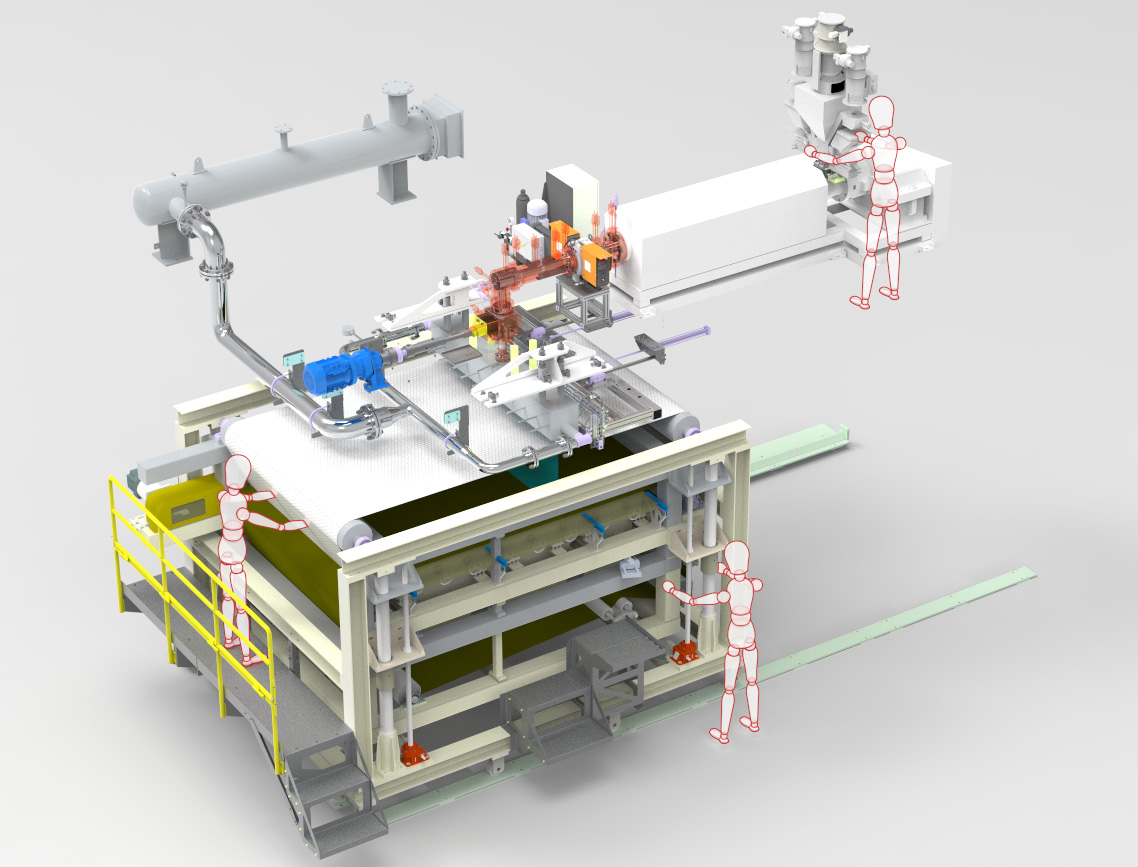

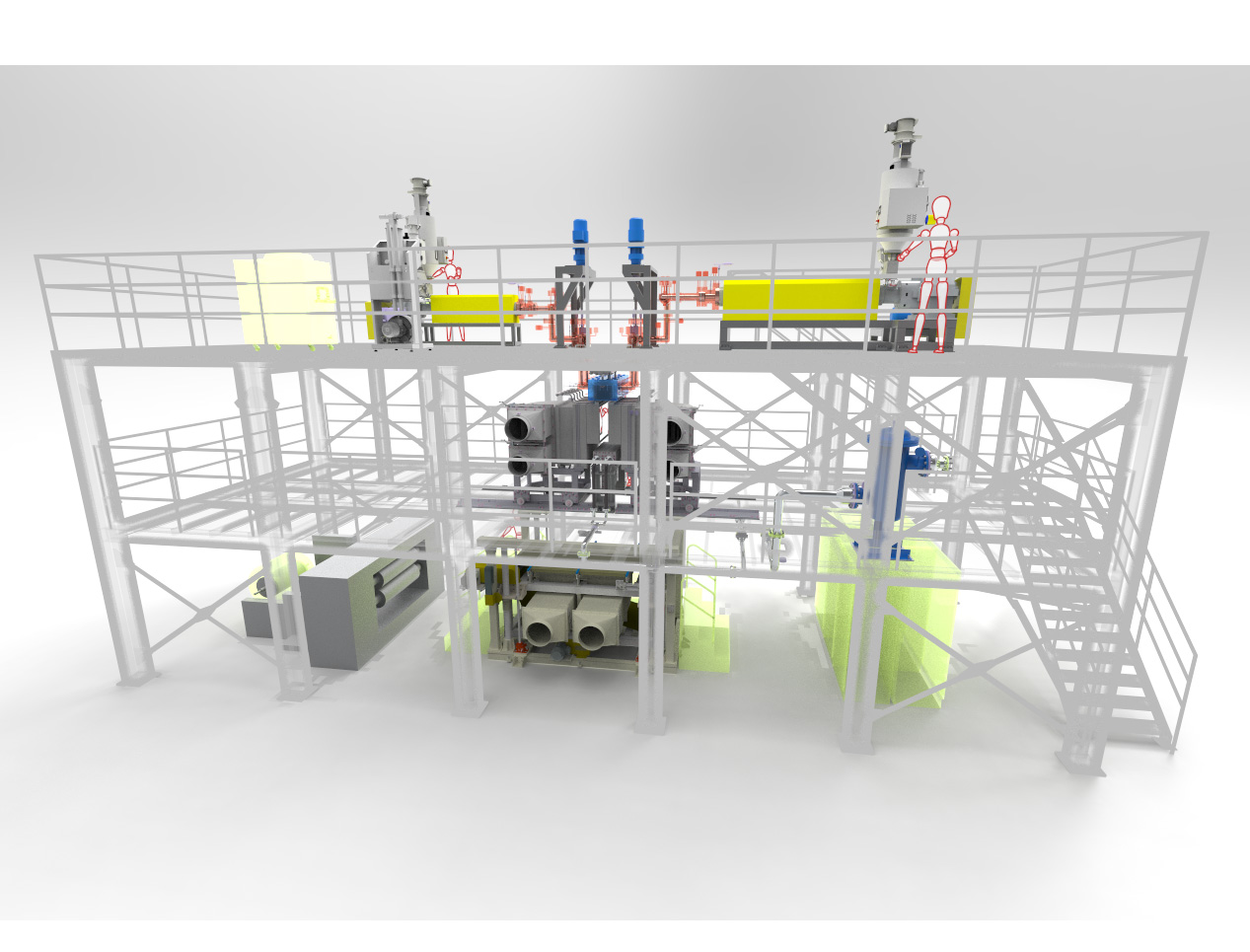

- Long nonwoven fabric facility

- Short nonwoven fabric facility

- Melt blown nonwoven fabric facility

- Turn-Key Base project (EPC)

Fabric facility

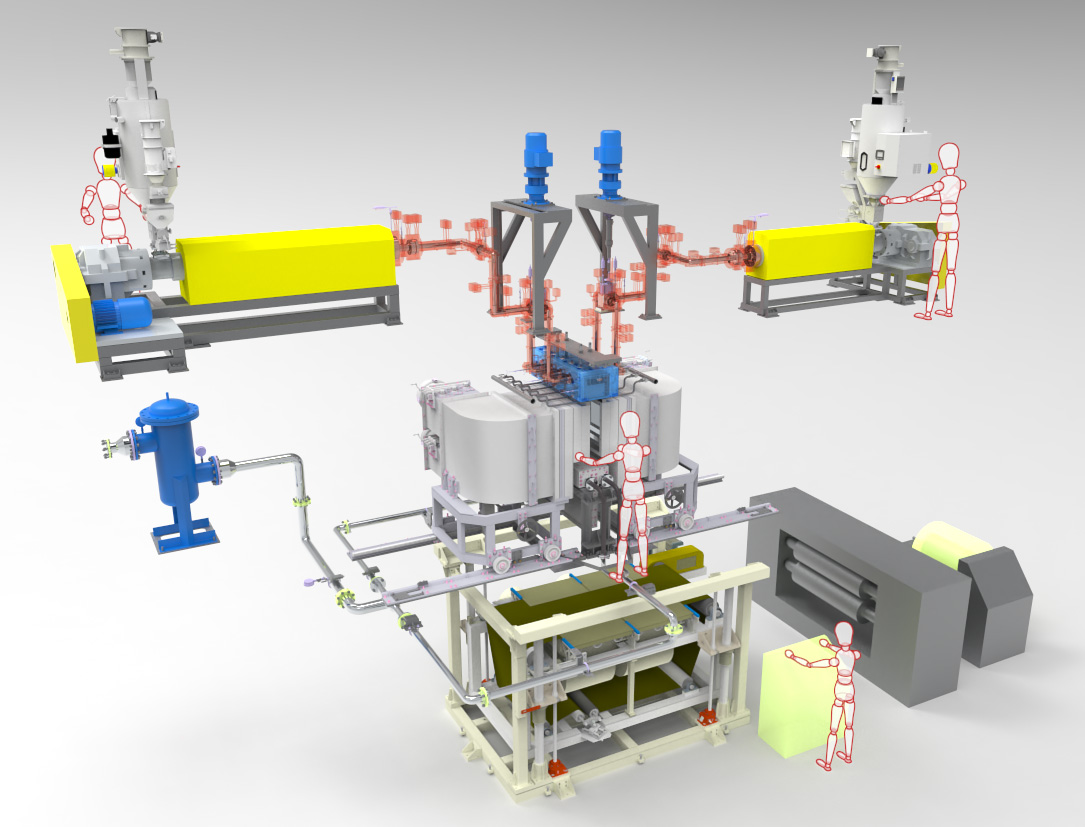

Spunbond process

-

Feeder, Dosing

Feeder, Dosing

-

ETR

ETR

-

S/C, G/P, Polymer Pipe

S/C, G/P, Polymer Pipe

-

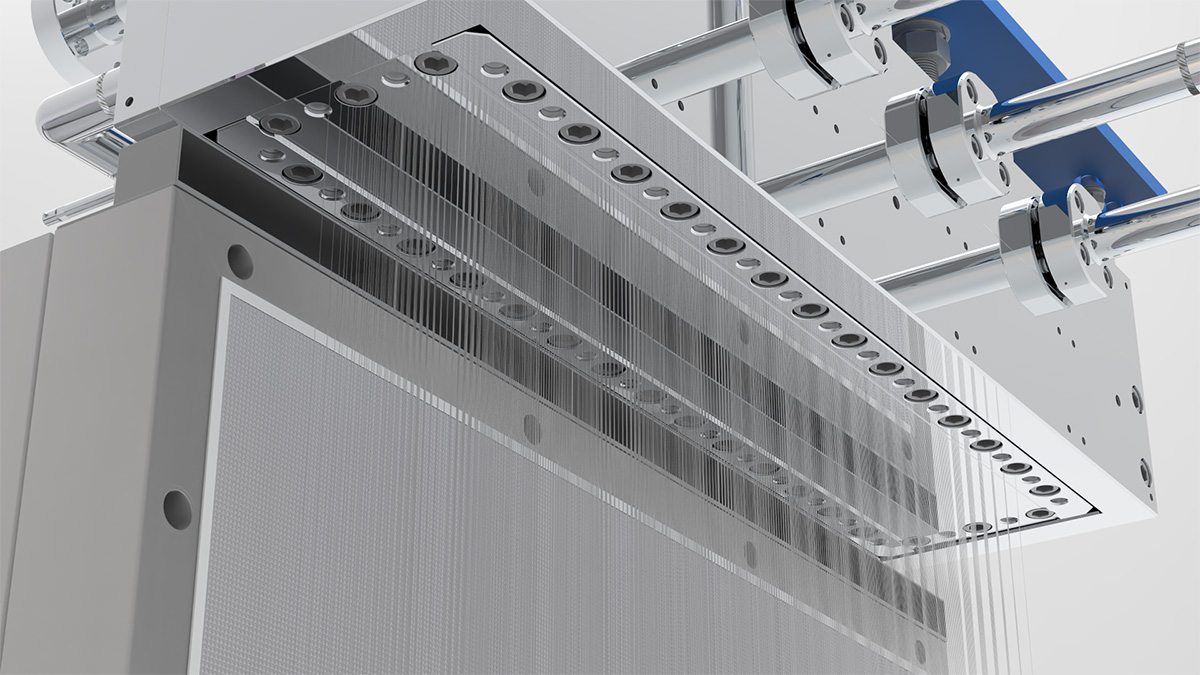

Spinning Block & Pack

Spinning Block & Pack

-

Quenching chamber

Quenching chamber

-

Elongation

Elongation

-

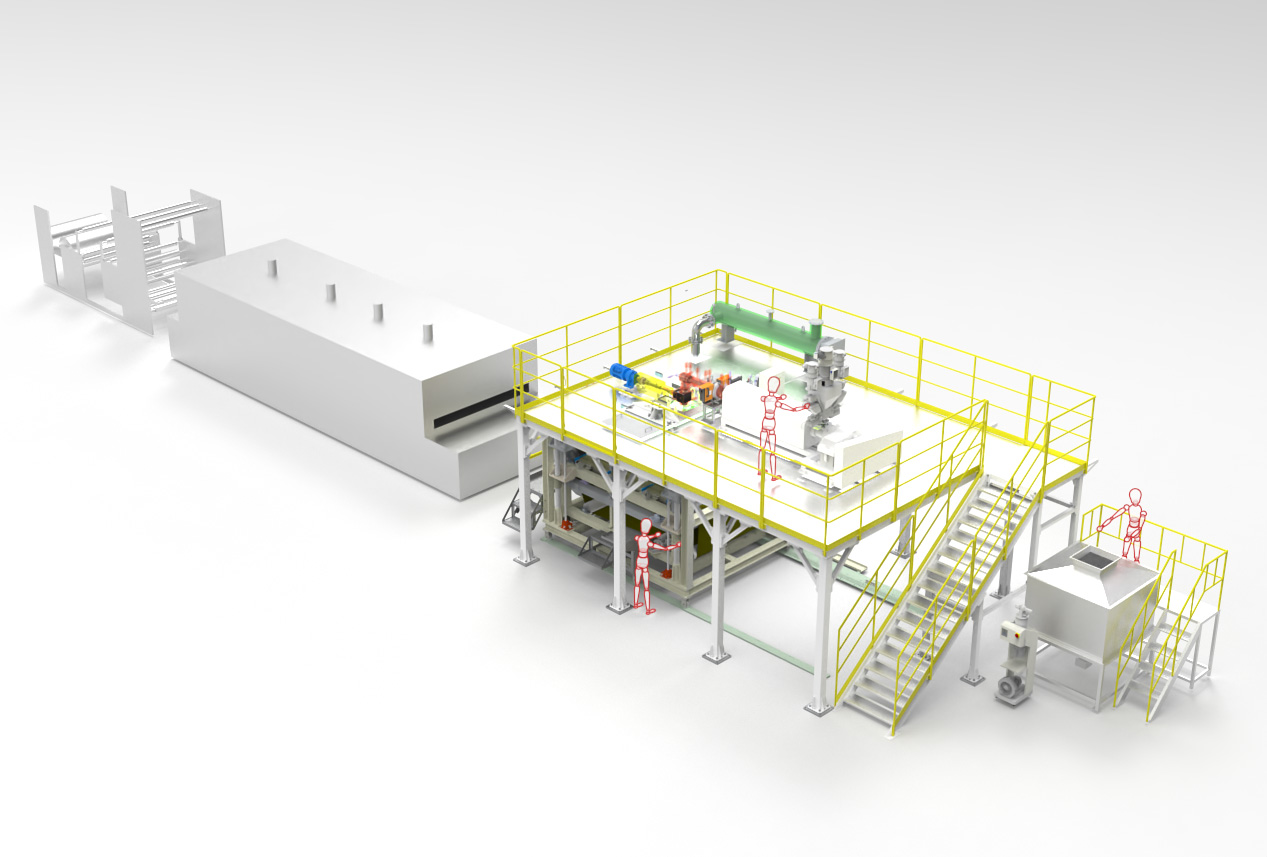

Web Forming

Web Forming

-

Winding

Winding

Melt blown process

-

Feeder, Dosing

Feeder, Dosing

-

ETR

ETR

-

S/C, G/P, Polymer Pipe

S/C, G/P, Polymer Pipe

-

Spinning Block & Pack

Spinning Block & Pack

-

Hydro Charging (wet and dry)

Hydro Charging (wet and dry)

-

Web Forming

Web Forming

-

Winding

Winding